Explore Our High Tensile Woven Wire Options

High Tensile Steel: High tensile steel is characterised by significantly higher strength and hardness compared to standard wire. There is a mild steel wire, which is half bright drawn and of weaving quality. However, High Tensile Steel exhibits superior tensile strength, yield strength, and resistance to deformation and fatigue and is most often used for woven wire mesh.

Corrosion Resistance: While high tensile woven wire exhibits good corrosion resistance, it may still be susceptible to rust and degradation over time, especially in harsh environments with high moisture or chemical exposure. It is important to consider the application and maintenance schedule which our team can best advise on.

Installation and Maintenance: Proper installation techniques and regular maintenance are essential to maximize the performance and longevity of woven wire high tensile steel. Issues such as improper tension, inadequate support, or lack of corrosion protection can lead to premature failure.

High Tensile Wire Thickness:

Wire Diameter

Thicker wires have a higher cross-sectional area, providing more material to withstand tension and compression forces. This directly enhances the mesh’s ability to bear loads and resist wear.

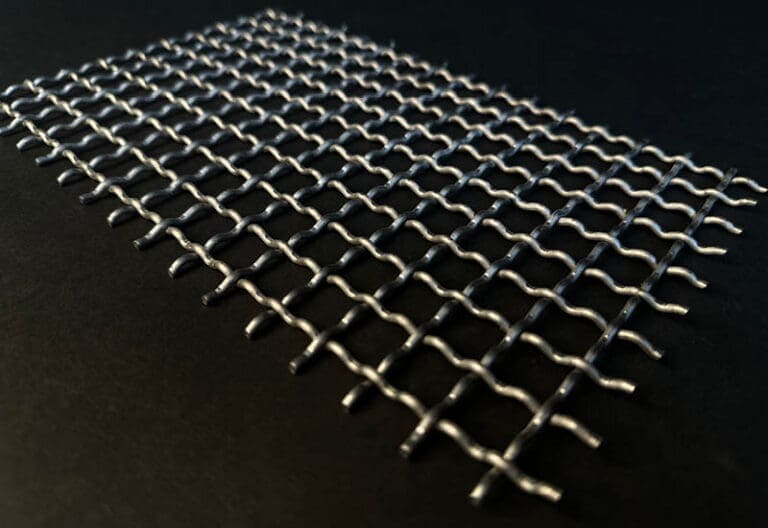

- Woven wire high tensile steel is available in various wire thicknesses (gauges), typically ranging from 10 gauge (0.135 inches) to 20 gauge (0.036 inches) or finer.

- Thicker wire gauges offer higher tensile strength and load-bearing capacity, making them suitable for heavy-duty applications such as fencing, security barriers, and industrial filtration.

- Finer wire gauges provide greater flexibility and mesh density, allowing for intricate weave patterns and finer filtration capabilities in applications such as insect screens, sieves, and decorative mesh.

Although High Tensile is a strong material ensure that you manufacture is one of quality as other factors contributing to strength include:

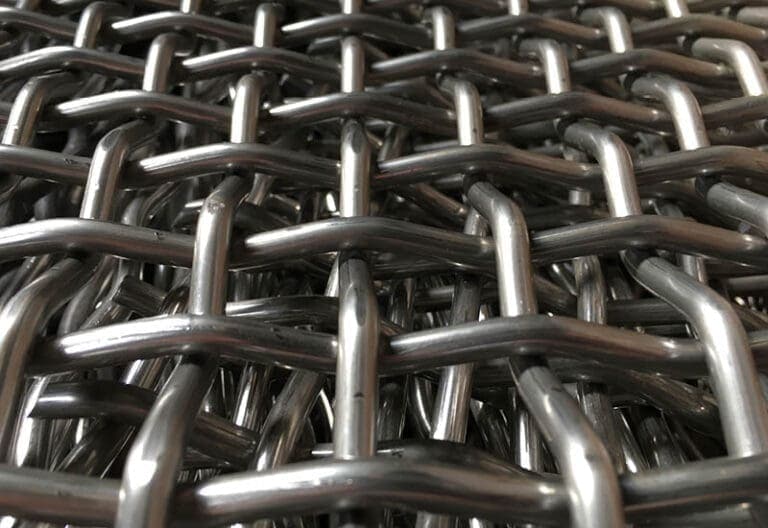

Weaving Technique

The method of weaving affects the distribution of stress across the mesh. Properly woven meshes ensure that stress is evenly distributed, reducing weak points, and increasing overall durability.

Aperture Size

Smaller apertures result in more wire per unit area, distributing the load across more material and reducing the risk of failure at any single point. This makes the mesh stiffer and more resistant to deformation.

Benefits of Woven Wire High Tensile:

Strength-to-Weight Ratio: Woven wire high tensile steel offers excellent strength-to-weight ratio, providing structural support and durability while minimising material weight and cost.

Versatility: Woven wire high tensile steel is highly versatile and adaptable to various applications, including fencing, screening, filtration, and architectural elements.

Customisation: The ability to customise wire thickness, mesh size, and weave patterns allows for tailored solutions to meet specific design requirements and performance criteria.

Longevity: Woven wire high tensile steel is known for its longevity and resistance to deformation, corrosion, and wear, resulting in reliable performance and reduced maintenance needs over time.